drying bottles in bags after autoclaving|dry cycle after autoclaving : mail order Post vacuum systems on small bench-top units will improve drying, whilst a jacketed pressure vessel is strongly recommended on larger units (see Fabrics and Textiles). Fabrics and . An autoclave conigured to run a Vacuum Cycle will be equipped with a vacuum system. Most autoclaves have two options for vacuum systems: a water ejector (with opt ional booster .

{plog:ftitle_list}

A temperature mapping of the assembled filters was performed and it was shown that the coldest spot was located at the sterile side at the top of the filter. The vertical position .

how to use autoclave for labware

Autoclave in paper sterilizing bags, allow the normal cool down period and store in a cool dry environment. There should be no condensation using this method .

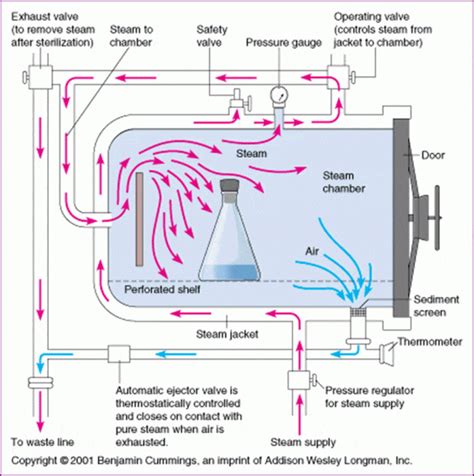

In healthcare, ensuring the sterility of medical instruments is crucial. Steam sterilization, or autoclaving, stands as a key defense against microbial contamination. Utilizing steam under pressure, this method .Autoclaving for 60–90 min at 121 °C (15 psi), depending on the loading conditions, to achieve a waste temperature of at least 115 °C for 20 min is recommended. Effective autoclaving will .Post vacuum systems on small bench-top units will improve drying, whilst a jacketed pressure vessel is strongly recommended on larger units (see Fabrics and Textiles). Fabrics and .

test biochimie

dry cycle after autoclaving

Nonhazardous dry goods: 30 minutes of sterilization plus 20 minutes of drying time. Dry time may need to be increased for enclosed items such as pipette tips or bottles with lids. Liquids (add .

Use RED biohazard bags: Avoid using red biohazard bags for autoclave waste. Red bags are typically reserved for other types of waste and may not be suitable for effective .Anyway those droplets are sterile, I've made culture media in fresh autoclaved bottles before, cells grow happily. . We have a large shared autoclave that technically has a dry/vacuum cycle, it .bag or container is suitable, since not all plastics They the autoclave chamber. b. Ensure that contaminated materials are free of sharp objects that may puncture bags. Autoclave bags are . There are many reasons behind the wet pack occurrences after autoclaving like poor quality of wrapping materials, faulty valves of rigid container, faulty loading and packaging .

After autoclaving finished (8 min sterilize, 40min dry), the bag was still wet, and the contents of the bag were still wet. Should I reautoclave the bag, or should i transfer them to a new bag an .

After cleaning, instruments should be rinsed with water to remove chemical or detergent residue. Take care to minimize splashing. Packaging. . Once dry, instruments . Dry heat sterilisation: hot air sterilisation at least 2 h at a minimum of 160 °C. . During the steam sterilisation of aqueous liquids in closed containers (infusion bottle, bag, . Figure 3. 1. Vessel. The vessel is the main body of the autoclave and consists of an inner chamber and an outer jacket. Laboratory and hospital autoclaves are constructed with .

Nonhazardous dry goods: 30 minutes of sterilization plus 20 minutes of drying time. Dry time may need to be increased for enclosed items such as pipette tips or bottles with lids. . The sterilizer manufacturer’s drying instructions should be followed; the typical recommendation is to open the door approximately one-half inch (1.25 cm) at the end of the .objects that may puncture bags. Autoclave bags are tear resistant, but can be punctured or burst in the autoclave. Fill bags only 2/3 full. Ensure adequate steam penetration by closing bags .

biochimie sanguine

1. Is it safe to autoclave all types of glass laboratory bottles? Before autoclaving lab bottles, it’s important to consider the suitability of different glass and bottle types. Borosilicate glass bottles .

Secure glass bottle caps before beginning the autoclaving process. Loose caps could cause glass bottles to explode under the pressure. If possible, aim to use borosilicate glassware. It has silica and boron trioxide as the main .

Autoclave in paper sterilizing bags, allow the normal cool down period and store in a cool dry environment. There should be no condensation using this method and if there is, have the .

Select appropriate containers or bags for collecting materials to be autoclaved. 5POLYPROPYLENE AUTOCLAVE BAG For biohazardous dry solid materials. a. Collect in .3. Don’t overfill containers, especially autoclave bags. About 2/3 full is appropriate, Overfull bags pose a greater risk of breakage, and also pose manual handling risks due to their weight. 4. . Oven, to dry washed labware and dry heat sterilization of glassware 11. Wire mesh baskets, to autoclave media in small vials and for drying labware. 12. Water distillation unit, .After autoclave sterilisation the chamber must cool down to a safe temperature before it can be opened. If you want to speed this process up you must be careful, using a rapid cooling .

Remove nipples and bottles during feeding time. After taking the bottle and its equipment from the solution, shake well and rinse with boiled and cooled water. Discard the .Autoclave sterilization of bottles. Autoclaving (121 °C, 15 minutes) in moist heat is convenient but requires a loose closure, to allow the steam to replace all the air during the temperature rise, .

Don’t bother autoclaving sterile tips! If they come sterile and in a sealed pack, they are sterile; don’t beat a sterile horse. Use the autoclave’s dry setting. The dry cycle is very bad .Bottles of liquid should not be more than 2/3 full. Keep 1-2 inches of space between bottles. After unloading from the autoclave, let the liquids cool for at least a full hour before touching with . The items in my autoclave are not drying and are coming out wet (i.e. wet packs) A wet pack can occur for any number of reasons. There is no single place to look first. There are, .

autoclave for dry cycles

Détails de l'article :Dimensions extérieures avec débord de toit : 428 x 367 cmDimensions du socle : 398 x 298 cmSurface de base : 10,07 m².Hauteur des parois latérales : env. 203 .

drying bottles in bags after autoclaving|dry cycle after autoclaving